Products:

Battery Holders

Capacitors

Connectors

Gas tubes

Heat Sinks

ICs >> STM32 microcontrollers

LCD Module

LED Display

LED Lens

LED Lights

LED Module

Materials

Miniature Speakers

Plastic & Hardware

Plastic profiled housings on a standard electric DIN rail

Potentiometers & Encoders

Resistors

Power Supplies

Power supply filters

Quartz Crystal

Switches

Test Probes

Thermistors

Varistors

|

|

Capacitors /

Radial Leaded MLCC

|

|

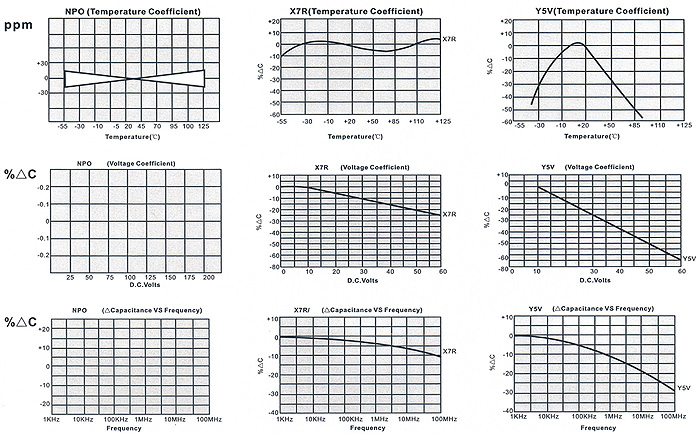

The choice of dielectric is largely determined by the temperature stability required

NPO (COG)

Ultra Stable Class I dielectric, with negligible dependence of electrical properties on temperature, voltage, frequency and time. Used in circuits requiring stable performance.

X7R (2X1)

Stable Class II dielectric, with predictable change of properties with temperature, voltage, frequency and time. Used as blocking, coupling, by-passing and frequency discriminating elements. This dielectric si ferroelectric and offers higher capacitance ranges than class 1.

Y5V (2F4) Z5U

General Purpose Class II dielectric with highest dielectric constant and greater variation of properties with Temperature and test conditions. Very high capacitance per unit volume and suited for bypass and coupling application as well as filtering, transient supression blocking, and charge storge application. |

CAPACITANCE VALUE & TOLERANCE

Determined by circuit requirements, Note that chip prices decrease with lower capacitance value and looser tolerances.

CAPACITOR TERMINATION

Termination choice is largely determined by the chip attachment method Nickel barrier is recommended for units exposed to repeated solder cycles, to preclude leaching fo the termination. Silver is used on units to be lead attached, as the more ductile silver minimizes thermal cycling hazards.

VOLTAGE

Determined by circuit requirements. Units are designed to exceed the withstanding voltage specification, i.e., The user need not incorporate an additional salty margin.

PACKAGING

Units are available in bulk, some sizes on tape & reel. Specify if reeled. |

GENERAL SPECIFICATIONS

| |

CC41 CC4 CC42

(NPO) |

CT41 CT4 CT42

(X7R) |

CT41 CT4 CT42

(Y5V, Z5U) |

| Capacitance Range |

0,1 PF - 0,22 μF |

100 PF - 2,2 μF |

1000 PF - 4,7 μF |

| Temperature Coefficient |

0±30PPm/°C

(-55°C...+125°C) |

±15°C

(-55°C...+125°C) |

30°C~80% (-25°C...+ 85°C)

22°C~56% (+10°C~ + 85°C) |

| Insulation Resistance |

C≤10nF R>10000MΩ

C>10nF C.R>100S |

C≤25nF R>4000MΩ

C>25nF C.R>100S |

| Dielectric Test Voltage |

2,5xWVDC |

| Dissipation Factor |

0,15%max ±0,2

(20°C, 1MHZ, 1VDC, 75%) |

2.5%max ±0,2

(20°C, 1KHz, 1VDC, 75%) |

3.5%max ±0,2

(20°C, 1KHz, 0,3VDC, 75%) |

| Voltage Ratings |

25, 50, 63, 100 V DC |

25, 50, 63 V DC |

| Capacitance Tolerances |

B = ±0.1PF

C = ±0.25PF

D = ±0.5PF

F = ±1%

G = 2%

J = ±5%

k = 10%

M = ±20%

(B.C.D for C<10PF) |

K= ±10%

M= ±20%

S = +50% / -20% |

M = ±20%

S = +50% / -20%

Z = +80% / -20%

P = +100% / -0% |

| Life Test (1000 hours) |

200% rated voltage at +125°C |

150% rated voltage at +85°C |

| Solderabillity |

GB9324-88 4,11 |

| Resistance to Soldering Heat |

GB9324-88 4,10 |

| Shock |

GB2693-90 4,17 |

| Temperature Cyling |

GB9324-88 4,12 |

| Moisture Resistance |

GB9324-88 4,14 |

| Termination adhesion strength |

GB9324-88 4,9 |

| Environment testing |

GB9324-88 4,13 |

TYPICAL CHARACTERISTICS

|

|